Aug 04 2023

Using Cement for Energy Storage

Imagine if every house, every building, came with 1-2 days (or possibly more) of energy storage. What if every wind turbine could store a day’s worth of the energy it produces on average? How beneficial would it be if the most common building material the world could be used to store energy? This prospect is not far fetched, and a new study by MIT scientists has already done a proof-of-concept.

Imagine if every house, every building, came with 1-2 days (or possibly more) of energy storage. What if every wind turbine could store a day’s worth of the energy it produces on average? How beneficial would it be if the most common building material the world could be used to store energy? This prospect is not far fetched, and a new study by MIT scientists has already done a proof-of-concept.

The material is cement, and what these researchers have demonstrated is that they can turn cement into a supercapacitor with another common material – carbon black. A capacitor is a device in which two conductive plates are separated by an insulating layer. This allows negative charge to build up on the positive plate and positive charge to build up on the negative plate, with the separated charges storing electrical energy. The Capacitors have several advantages for energy storage devices – they can store and discharge energy very quickly, they are relatively simple to construct, and they have almost endless charge and discharge cycles. But they also have one major disadvantage, they store very little energy per volume or mass.

As I discussed previously, current lithium ion batteries have energy densities up to 265 Wh/kg. The new Amprius lithium ion batteries with silicon anodes have an energy density of 500 Wh/kg. A typical supercapacitor (just a high energy density capacitor) has an energy density of 16 Wh/kg. My previous article was about a carbon nanofiber supercapacitor with energy density up to 73 Wh/kg – very high for a supercapacitor, but still tiny compared to cutting edge lithium ion batteries.

For an application like a car, a supercapacitor simply holds too little energy. But they could supplement the battery, and would increase the efficiency of regenerative braking. Future EVs might combine a battery and a supercapacitor to get the best of both worlds. Also, if the body of the car itself could be constructed out of a supercapacitor, that could add range and efficiency without adding any weight to the car.

Grid storage is a different situation entirely. With grid storage, or backup storage for individual buildings or structures, we don’t really care about weight. You can have a heavy massive battery that is just sitting in one spot. Energy storage capacity per volume is more important than per mass, and low energy per volume is acceptable if you have enough space. What arguably matters most is that the raw materials used are cheap and abundant, and the energy storage is easy to mass produce. What could be better than if we could turn cement into a supercapacitor? The world uses 4 billion metric tons of cement per year. That is a lot of potential energy storage.

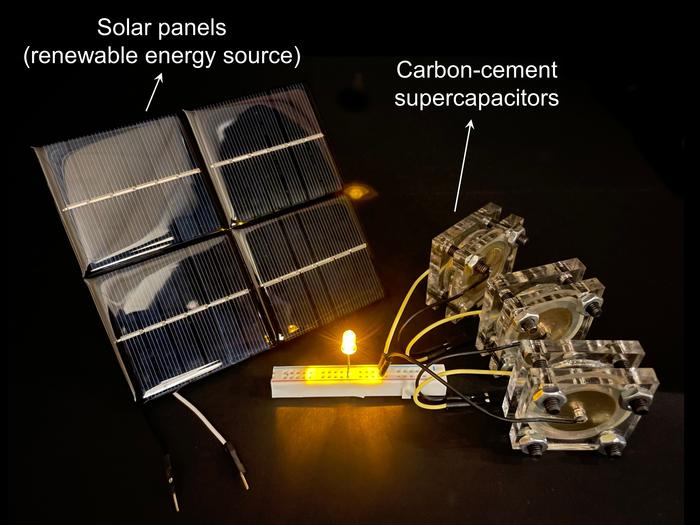

What the MIT scientists did is dope cement with carbon black. When cured with water the cement naturally forms pockets, which then fill with the carbon black. Once solidified you end up with a meshwork of conducting carbon in the insulating cement – a giant capacitor. The meshwork also has a fractal pattern, with smaller and smaller branches of carbon, leading to a massive internal surface area. It’s the surface area which determines the storage capacity of the capacitor. The researchers had to find the optimal ratios of cement, carbon black, and water, and it appears they did. Now they need to keep going – creating bigger and bigger blocks of the stuff and testing its properties. Their goal is to create 45 cubic yard block of this cement, which should store about enough energy to run an average American home for one day. That is also about the amount of cement a typical house has in its foundation. Actually I found one calculation that put the figure at 66 cubic yards.

Now comes the fun part. Imagine if this all works out – the supercapacitor cement scales to large volume, and can be efficiently mass produced. It might then be possible for every new building to come with its own energy storage, enough for 1-3 days. Foundations could be made to be more robust than they have to be, in order to maximize the volume of supercapacitor cement and therefore power storage. Every wind turbine could be built on a cement platform that could also store energy to buffer the ups and downs of the wind. Grid solar can also be placed on such platforms. Power plants could be their own grid storage. Just think about how ubiquitous cement is – if even a small percentage were made from this supercapacitor material that could potentially meet our grid storage needs.

I also like to wonder how good this technology can get. There is an appeal to using common materials, like carbon black. But what if we combine this idea with the carbon nanotube supercapacitor idea? Would that boost storage, and by how much? We don’t need to make long strands of carbon nanofibers, just flawed short ones will do for this kind of filler. This increases the strength of the cement, and carbon nanotubes are highly conductive.

Also – cement production releases a lot of carbon – 1.5% of total worldwide CO2 release. This is a small but significant amount. But there are already in the works carbon neutral forms of cement. We need to combine these technologies with the cement supercapacitor technology. Even better, if we are going to fantasize, what if we capture carbon from the air or industrial production and use that carbon to make the cement?

But I would happily settle for the current version of this technology, if it scales and can be cheaply and efficiently integrated into current cement production and use. I don’t like to think in terms of a single solution to a complex problem, but this technology could potentially be one significant addition to our transition to a green energy sector. Adding energy storage is a huge advantage to transitioning to renewable energy sources.