Nov 02 2021

Making Biofuel on Mars

NASA and China are both planning on sending people to Mars sometime in the 2030s. This is an ambitious goal and I would be pleasantly surprised if either hit that target. Sometime in the 2040s, and only if plans go fairly well, may be more realistic. There are many challenges to such a mission. NASA’s plan is to work out most of the technology by going back to the Moon first, setting up a semi-permanent presence there, and essentially using it as a stepping stone to Mars.

But Mars presents some of its own challenges, primarily, of course, the distance. Just getting to Mars and back is pushing the limits of how long astronauts can safely stay in space due to radiation exposure. There are no practical plans for shielding from cosmic rays (solar radiation is more manageable) and so NASA’s plan is just to keep missions within the three year safety window.

Another challenge Mars does not share with missions to the Moon is sourcing the fuel for a return trip. If you recall the rocket equation, the more fuel you need to get to your destination, the more fuel you need to carry that fuel, and so on. So small changes in weight and the needed change in velocity can lead to huge increases in fuel needs. We can get to the Moon with enough fuel to get back. We cannot get to Mars with enough fuel to get back. A mission to Mars will need to refuel on Mars in order to make the return trip. Robotic missions to Mars are one-way trips, so this has not been an issue before, but we would like to get our astronauts back home.

There are two options for refueling. The first is that we send the fuel needed for a return trip ahead of the mission, so it is waiting there when the astronauts arrive. This is the current plan, and is likely what will happen. The second option, however, is to make fuel on Mars from local resources. The potential advantage here is that once the equipment is sent to Mars, set up and functioning, there would be a continuous source of fuel. This could serve multiple missions, and even a settlement on Mars. Researchers, therefore, are looking for ways to make this happen.

A recent paper outlines one potential method. What is needed for rocket fuel is a propellant and an accelerant, two components that will be burned together. The accelerant is liquid oxygen. The propellant can be a number of things, with liquid hydrogen and methane being two popular propellants used in launching rockets from Earth. Neither of these exist on Mars, but could theoretically be created. Hydrogen can be split from water, which would create both the propellant and accelerant in one process. There is likely water in the crust of Mars but getting at sufficient volumes of it will be tricky. You can also split oxygen from CO2 in the atmosphere, combine that with water in a process that makes methane.

The researchers in the new study, however, realized an important fact – Mars has only 38% of the gravity as on Earth. This means that fuels which are not suitable for rockets on Earth can work just fine for getting off of Mars. The rocket equation essentially limits rocket fuels to a minimum necessary energy density. In fact, on a planet with a surface gravity of only 1.5 G, no chemical rockets could get into orbit. Chemical energy is simply not energy dense enough. Something like nuclear powered rockets would be necessary.

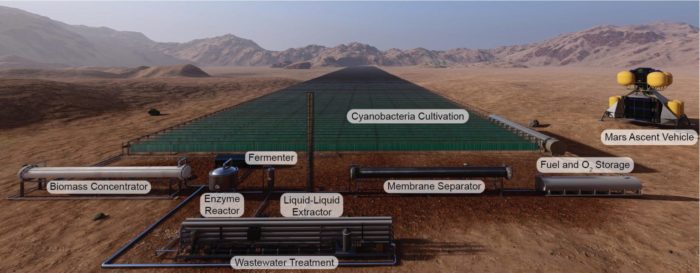

With an expanded list of potential rocket fuels for Mars, the researchers considered 2,3-butanediol (2,3-BDO). They outlined a process by which, “Photosynthetic cyanobacteria convert Martian CO2 into sugars that are upgraded by engineered Escherichia coli into 2,3-BDO.” We would need about four football fields of bioreactors powered by sunlight to grow the cyanobacteria and E. coli. The 2,3-BDO can then be purified from the bioreactors with the E. coli. The process will produce about 44 tons of excess oxygen, which can be stored for use by the astronauts or later use on Mars.

The downside is that the total equipment weight is 2.8 times the weight of chemical in situ fuel strategies. With optimization the researchers believe they can get the weight down by 13%, but still this is more weight. That might be a deal-killer – weight is everything when calculating costs of missions to Mars. There are a couple of advantages, however. The process uses less energy than the chemical fuel processes. Energy is likely to be a limiting resource for any Mars missions or settlement as well. Also, the process and equipment can easily be repurposed for making food. It also produces excess oxygen for other uses.

Even if a process like this is not used for the initial Mars missions, using bioreactors to make biofuel may be a good long term strategy for a settlement on Mars. It can produce food, fuel, and oxygen in an energy efficient process. This may be worth the initial investment in increased weight of equipment to ship to Mars. It may also be possible for equipment redesign to reduce the needed weight further. By the time missions are actually blasting off to Mars, there will have been a lot of time for technological advances. And of course, developing this technology further has potential uses on Earth.