Feb 21 2025

Thermoelectric Cooling – It’s Cooler Than You Think

I am fascinated by the technologies that live largely behind the scenes. These are not generally consumer devices, but they may be components of consumer products, or may largely have a role in industry – but they make our modern world possible, or make it much better. In addition I think that material science is largely underrated in terms of popular appeal, but it is material science that often make all other technologies possible or feasible. There is another aspect of technology that I have been increasingly interested in – solid state technology. These are, generally speaking, devices that use electricity rather than moving parts. You are likely familiar with solid state drives, that do not have spinning discs and therefore are smaller, use less power, and last longer. One big advantage of electric vehicles is that they are largely solid state, without the moving parts of an engine.

I am fascinated by the technologies that live largely behind the scenes. These are not generally consumer devices, but they may be components of consumer products, or may largely have a role in industry – but they make our modern world possible, or make it much better. In addition I think that material science is largely underrated in terms of popular appeal, but it is material science that often make all other technologies possible or feasible. There is another aspect of technology that I have been increasingly interested in – solid state technology. These are, generally speaking, devices that use electricity rather than moving parts. You are likely familiar with solid state drives, that do not have spinning discs and therefore are smaller, use less power, and last longer. One big advantage of electric vehicles is that they are largely solid state, without the moving parts of an engine.

There is a technology that combines all three of these features – it is a component technology, dependent on material science, and solid state: thermoelectric devices. This may not sound sexy, but bear with me, this is cool (pun intended) technology. Thermoelectric materials are those that convert electricity into a temperature difference across a material, or convert a temperature difference into electricity. In reality, everything is a thermoelectric material, but most materials have insignificant thermoelectric effects (so are functionally not thermoelectric).

Thermoelectric devices can be used to harvest energy, from any temperature difference. These are generally not large amounts of energy – we don’t have thermoelectric power plants connected to the grid – and they are currently not practical and cost effective enough for a large scale. This may be possible in the future, but not today. However, for applications that require small amounts of energy, harvesting that energy from ambient sources like small temperature differences is feasible.

There are likely many more applications for the reverse – using electricity to cause temperature changes. This is basically a refrigerator, and in fact y0u can buy small solid state thermoelectric refrigerators. A traditional refrigerator uses a compressor and a refrigerant. This is a liquid that turns into a gas at low temperature, absorbing heat when it transitions to gas and then letting off heat when it transitions back to liquid. But this requires a compressor with moving parts and pipes to carry the refrigerant. Refrigerants are also not good for the environment or the ozone. Thermoelectric coolers can be smaller, use less electricity, are quiet, and have more precise temperature control. But their size is limited because they are not powerful enough for full-sized refrigerators.

As an aside, I see that Samsung is coming out this year with a hybrid full-size refrigerator. I still uses a compressor, but also has a thermoelectric cooler to reduce temperature variation throughout the refrigerator.

Thermoelectric cooling is also useful for electronics, which having an increasing problem with heat dissipation as we make them smaller, more compact, and more powerful. Heat management is now a major limiting factor for high end computer chips. This is also a major limiting factor for bio-electronics – implanting chips in people for various potential applications. Having a small and efficient solid state cooling device that just requires electricity would enable this technology.

But – the current state of the art for thermoelectric cooling is limited. Devices have low overall efficiency, and their manufacture is expensive and generates a lot of waste. In other words – there is a huge opportunity to improve this technology with massive and far ranging potential benefits. This is an area ripe for investment with clear benefits. This can also be a significant component of our current overall goal to electrify our technology – to accomplish with electricity what currently requires moving parts and fossil fuels.

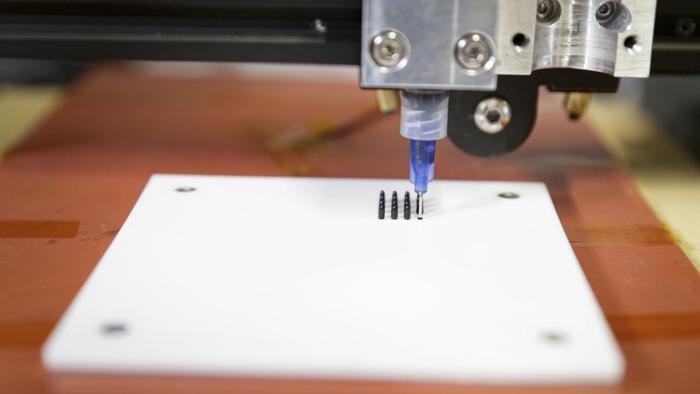

All this is why I was very interested in this latest advance – Interfacial bonding enhances thermoelectric cooling in 3D-printed materials. This incorporates yet another technology that has my interest – 3D printing, or additive manufacturing. This does not represent an improvement in the thermoelectric devices themselves, but an improvement in the cost and efficiency of making them (again, and often neglected by very important aspect of any technology). As one of the authors says:

“With our present work, we can 3D print exactly the needed shape of thermoelectric materials. In addition, the resulting devices exhibit a net cooling effect of 50 degrees in the air. This means that our 3D-printed materials perform similarly to ones that are significantly more expensive to manufacture,” says Xu.”

The innovation has to do with the molecular bonding of the materials in the 3D printing process. As Xu says, the performance is the same as existing materials, but with much lower cost to manufacture. As always, shifting to a new technology often means that there is room for further incremental advances to make the advantages even better over time. It may take years for this technology to translate to the market, but it is very possible it may lead directly to a slew of new products and applications.

It may seem like a small thing, but I am looking forward to a future (hopefully not too distant) with full-sized thermoelectric refrigerators, and with computers that don’t need fans or water cooling. Having a silent computer without fans is nice for podcasting, which I know is a particular interest of mine, but is also increasingly common.

In general, quality of life will be better if we are surrounded by technology that is silent, small, efficient, cost-effective, and long-lasting. Thermoelectric cooling can make all of that increasingly possible.