Aug 21 2023

Gradient Nanostructured Steel

Science fiction writers, who have to think deeply about the possible nature of future technology, often invent new sci-fi materials in order to make their future technology seem plausible. They seem to understand the critical role that material science plays in advancing technology. This is why sci-fi is full of fictional materials such as unobtainium, vibranium, adamantium, and carbonite (to name just some of the most famous ones). New materials change the limits of what’s possible. There is only so much that technology can do within the limits of existing materials.

Science fiction writers, who have to think deeply about the possible nature of future technology, often invent new sci-fi materials in order to make their future technology seem plausible. They seem to understand the critical role that material science plays in advancing technology. This is why sci-fi is full of fictional materials such as unobtainium, vibranium, adamantium, and carbonite (to name just some of the most famous ones). New materials change the limits of what’s possible. There is only so much that technology can do within the limits of existing materials.

In fact the early stages of human technology are defined by the materials they used, from the stone age to the iron age. Today we live in the steel age, more than 3,000 years after steel production came into existence. There are many advanced materials with different applications, but in many ways steel still defines the limits of our technology. This is why research looking for ways to improve the characteristics of modern steel is still going on. A recent study might be pointing the way to one method of pushing the limits of steel.

Steel is simply an alloy of iron combined with a small percentage of carbon. Carbon atoms bind with the iron atoms to make crystals of steel that are harder and stronger than iron by itself. The properties of steel can be adjusted by the percentage of carbon in the alloy. The properties of the resulting steel can also be altered by alloying other metals with the steel as well- molybdenum, manganese, nickel, chromium, vanadium, silicon, and boron, for example. These can make the steel stronger, tougher, more ductile, heat resistant, or rust resistant.

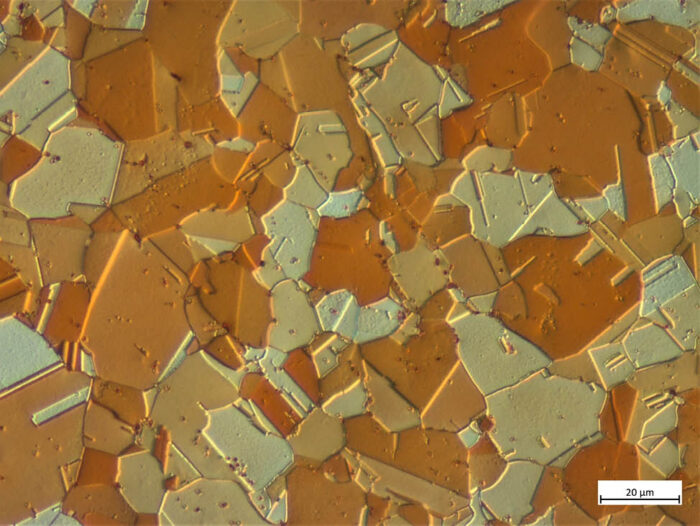

But there is another way to manipulate the properties of steel – through heat treatment. This likely took several hundred years to discover and perfect after steel itself was discovered. You can anneal steel, which involves heating it to its Curie temperature, the point at which it loses its magnitism (which means it loses its crystal structure), and then cool it very slowly, allowing large grains to grow. This makes the steel soft, ductile, and strong. You can also quench (quickly cool) some types of steel which will cause the steel to for fine grains that make it hard, but brittle. Tempering steel is the process of heating it to a temperature below it’s Curie temperature for a period of time, which can add back some strength to the steel. Getting the temperatures and timing correct for different alloys of steel took a lot of trial and error. You can also combined different types of steel in laminated layers to get the best of different properties. This basic steel technology is still used today.

But now we have another way to alter the properties of steel, by influencing its nanostructure. This is possible because we can examine its nanostructure using advanced imaging techniques. This is where the current study comes in. The authors write:

Nanostructured metallic materials with abundant high-angle grain boundaries exhibit high strength and good radiation resistance. While the nanoscale grains induce high strength, they also degrade tensile ductility. We show that a gradient nanostructured ferritic steel exhibits simultaneous improvement in yield strength by 36% and uniform elongation by 50% compared to the homogenously structured counterpart.

They took T-91 steel and used compression and shear stresses to break up larger grains into smaller grains (resulting in GT-91). The process resulting in a smooth gradient of grain size, from very small at the surface to progressively larger toward the center, as much as 100 times larger. This creates hard steel at the surface and strong steel at the center (good for sword making, but other applications as well). Yield strength, as referred to above, is the amount of force the steel can withstand and still return to its original shape, without being permanently deformed. High yield strength is therefore important in many applications, such as springs. Uniform elongation is a measure of ductility, which is the amount by which the steel can be deformed before it breaks. Usually these two properties are a trade off, if you increase one you decrease the other. But the GT-91 has increased in both properties compared to the original T-91.

The authors mention another property of this steel that will likely be very important in the future – radiation resistance. This is the ability of the steel itself to withstand radiation without becoming brittle. This is an important property for nuclear reactors, possible fusion reactors, and probes and spaceships for deep space missions.

It’s good to see that we continue to make significant advances in steel technology. It’s possible steel will remain a critical material for our technology for a few more thousand years. But I do wonder what the limits of steel technology are. What will steel look like in a thousand years? How far can we push the properties of steel? I also have to wonder what entirely new materials are out there waiting to be invented. There are no new elements to discover that can replace steel. We have filled in the periodic table, and now are only adding new elements to the end, with high atomic numbers and unstable properties. There is no vibranium waiting to be discovered as a new element.

Fictional metals therefore must be new alloys with nanostructured properties, or perhaps some kind of metamaterial properties. Knowing what the theoretical limits are of such materials is important to thinking about future technologies such as space elevators (likely not feasible) interstellar space ships, and solar sails. There is also the possibility of non-metal futuristic materials, such as some type of carbon nanofiber, or something else not even imagined so far. Material science is fascinating because it has the potential to completely change the game, making new technologies and applications possible. Even just incrementally improving steel can have a huge impact.