Jan 18 2024

Converting CO2 to Carbon Nanofibers

One of the dreams of a green economy where the amount of CO2 in the atmosphere is stable, and not slowly increasing, is the ability to draw CO2 from the atmosphere and convert it to a solid form. Often referred to as carbon capture, some form of this is going to be necessary eventually, and most climate projections include the notion of carbon capture coming online by 2050. Right now we don’t have a way to economically and on a massive industrial scale pull significant CO2 from the air. There is some carbon capture in the US, for example, but it accounts for only 0.4% of CO2 emissions. It is used near locations of high CO2 production, like coal-fired plants.

One of the dreams of a green economy where the amount of CO2 in the atmosphere is stable, and not slowly increasing, is the ability to draw CO2 from the atmosphere and convert it to a solid form. Often referred to as carbon capture, some form of this is going to be necessary eventually, and most climate projections include the notion of carbon capture coming online by 2050. Right now we don’t have a way to economically and on a massive industrial scale pull significant CO2 from the air. There is some carbon capture in the US, for example, but it accounts for only 0.4% of CO2 emissions. It is used near locations of high CO2 production, like coal-fired plants.

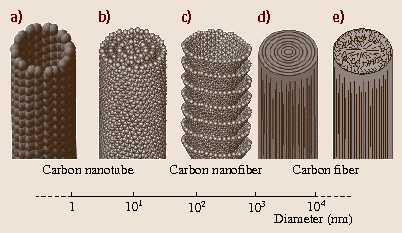

But there is a lot of research being done, mostly in the proof of concept stage. Scientists at the DOE and Brookhaven National Laboratory have published a process which seems to have promise. They can convert CO2 in the atmosphere to carbon nanofibers, which is a solid form of carbon with potential industrial uses. One potential use of these nanofibers would be as filler for concrete. This would bind up the carbon for at least 50 years, while making the concrete stronger.

In order to get from CO2 to carbon nanofibers they break the process up into two steps. They figured out a way, using an iron-cobalt catalyst, to make carbon monoxide (CO) into carbon nanofibers. This is a thermocatalyst process operating at 400 degrees C. That’s hot, but practical for industrial processes. It’s also much lower than the 1000 degrees C required for a method that would go directly from CO2 to carbon nanofibers.

That’s great, but first you have to convert the CO2 to CO, and that’s actually the hard part. They decided to use a proven method which uses a commercially available catalyst – palladium supported on carbon. This is an electrocatalyst process, that converts CO2 and H2O into CO and H2 (together called syngas). Both CO and H2 are high energy molecules that are very useful in industry. Hydrogen, as I have written about extensively, has many uses, including in steel making, concrete, and energy production. CO is a feed molecule for many useful reactions creating a range of hydrocarbons.

But as I said – conversion of CO2 and H20 to CO and H2 is the hard part. There has been active research to create an industrial scale, economic, and energy efficient process to do this for years, and you can find many science news items reporting on different processes. It seems like this is the real game, this first step in the process, and from what I can tell that is not the new innovation in this research, which focuses on the second part, going from CO to carbon nanofibers.

The electrocatalyst process that goes from CO2 to CO uses electricity. Other processes are thermocatalytic, and may use exothermic reactions to drive the process. Using a lot of energy is unavoidable, because essentially we are going from a low energy molecule (CO2) to a higher energy molecule (CO), which requires the addition of energy. This is the unavoidable reality of carbon capture in general – CO2 gets released in the process of making energy, and if we want to recapture that CO2 we need to put the energy back in.

The researchers (and pretty much all reporting on CO2 to CO conversion research) state that if the electricity were provided by a green energy source (solar, wind, nuclear) then the entire process itself can be carbon neutral. But this is exactly why any type of carbon capture like this is not going to be practical or useful anytime soon. Why have a nuclear power plant powering a carbon capture facility, that is essentially recapturing the carbon released from a coal-fired plant? Why not just connect the nuclear power plant to the grid and shut down the coal-fired plant? That’s more direct and efficient.

What this means is that any industrial scale carbon capture will only be useful after we have already converted our energy infrastructure to low or zero carbon. Once all the fossil fuel plants are shut down, and we get all our electricity from wind, solar, nuclear, hydro, and geothermal then we can make some extra energy in order to capture back some of the CO2 that has already been released. This is why when experts project out climate change for the rest of the century they figure in carbon capture after 2050 – after we have already achieved zero carbon energy. Carbon capture prior to that makes no sense, but after will be essential.

This is also why some in the climate science community think that premature promotion of carbon capture is a con and a diversion. The fossil fuel industry would like to use carbon capture as a way to keep burning fossil fuels, or to “cook their books” and make it seem like they are less carbon polluting than they are. But the whole concept is fatally flawed – why have a coal-fired plant to make electricity and a nuclear plant to recapture the CO2 produced, when you can just have a nuclear plant to make the electricity?

The silver lining here is that we have time. We won’t really need industrial scale carbon capture for 20-30 years, so we have time to perfect the technology and make it as efficient as possible. But then, the technology will become essential to avoid the worst risks of climate change.