Jan 04 2016

The Coming 3-D Printer Revolution

I am a technophile, so I follow new and emerging technologies pretty closely. I am also an occasional early adopter, as much as my finances allow, which is not anywhere close to what I would like. Often I must wait for a new technology to come down in price to the consumer level, or at least the “prosumer” level.

I am a technophile, so I follow new and emerging technologies pretty closely. I am also an occasional early adopter, as much as my finances allow, which is not anywhere close to what I would like. Often I must wait for a new technology to come down in price to the consumer level, or at least the “prosumer” level.

Over the last couple of years I have had my eye on 3-D printers. This is an extremely promising technology, often referred to as additive manufacturing. Traditional manufacturing methods start with a block of material and then take away material to create the shape, or they use some kind of mold, or they hammer, pull, bend, or press material into shape.

Additive manufacturing adds material to “print” the desired object in three dimensions. The huge advantage here is that the process allows for open-ended computer-controlled creation. If you have a design of an object on your computer, the 3-D printer can make it.

Where is 3-D Printing Now?

Right now I would say we are in the early adopter/professional phase of 3-D printing technology. However, we are right on the brink of widespread consumer adoption. One rule of thumb is that the price break for an appliance to be considered at the widespread consumer adoption level is $1,000 (this, of course, depends on utility and necessity). We saw this with digital cameras, laser printers, DVD and then Blu-Ray players, and flat-screen TVs.

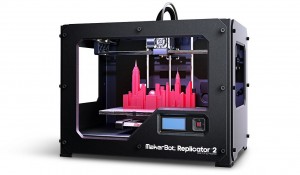

Already 3-D printers have fallen below the magical $1,000 mark. Here is a Maker 3-D printer for $300. Better prosumer level printers are in the $3-5k level, and you can spend over $6k on a professional printer.

The variables to consider are this: the build size (how large an object can the printer create?), the material used, and the resolution. Speed is also an issue, as it can take hours to create a single item, but unless you are producing a lot of items this is not a huge concern. There are, of course, also the generic quality concerns, like reliability, lifespan, support, ease of use, etc.

Right now there are printers that can use plastic, resin, or even metal. There are also printers that use ceramics, but these will likely remain in the realm of professional use because they require the end product to be heated to high temperatures to fuse the ceramic particles and melt away the binding resin.

There is a new proposed technique that prints using a pre-ceramic plastic that is then heated to 1,000 degrees C to form a high quality ceramic.

The price and quality of objects created are now sufficient, in my opinion, for widespread adoption. So why wasn’t a cheap 3-D printer the hot holiday gift of 2015? What is holding back widespread consumer adoption? I think right now the 3-D printer is missing the killer app.

Printers are used now by those who need to make prototypes, or who need one-off specialty items (like a specific part to a vintage car). Companies that need such parts can create them faster and cheaper in-house with a professional printer. Meanwhile early adopters are playing around with the printers, seeing what they can do.

Why, however, would the average consumer want to have one in their house as a serious appliance? Until there is a good answer to that question I don’t think we will see a 3-D printer in every home.

The Future of 3-D Printing

It is not difficult to imagine, however, how 3-D printers can become as common as microwave ovens. Imagining is easy – predicting is more difficult. The microwave oven is a great example – it was developed as a cooking appliance, a task at which it utterly failed. It became indispensable as a heating appliance, however.

Smart phones are perhaps another illustrative example. They were hitting the market for a few years before they took off, which resulted more from the existence of an app store than advances in the technology itself.

We can look at the 3-D printer from two perspectives, the technology itself and the potential applications. The technology is advancing nicely. This advancement includes better resolution, a greater variety of materials, and tougher and therefore more versatile end-products. Three-D printing will also benefit from advances in computers and software.

How would the average consumer use their 3-D printer? One problem for widespread adoption is that for most common objects it is cheap and easy to buy them at the local store, or even to have them delivered to your home. Aside from the novelty, what is the advantage of printing an object yourself?

The big advantage as I see it is customization and personalization. If you could design the object from potentially millions of options, that would be something not currently available at WalMart. You could also easily add your own personalized designs or elements.

Another use is printing replacement parts. Most people have had the experience of having one small plastic piece on an appliance break, essentially ruining the appliance. Often you cannot buy just that one piece. The company would rather sell you a new appliance.

What if, however, you could go to the company website, download the specs for that one piece, and then print a replacement yourself at home – appliance fixed.

These applications involve using 3-D printers to accomplish existing tasks. The real killer apps will come, however, when people figure out how to use home 3-D printers in ways not currently available.

In other words, when appliances and devices are designed and optimized for the home 3-D printer, the printer will really come into its own. For example, imagine if an appliance were designed to incorporate components made from available 3-D printers, allowing for a wide range of customization. Along with the appliance you would get custom software that walked the consumer through designing and printing their custom options.

Another type of application is unleashing individual creativity. Everyone could become a sculptor, using software to design their artistic objects, and then printing them in the desired medium. The ability to virtually create something, and then have it as a real 3-D object, could become addictive.

We may get to the point that custom 3-D software is as common as a company website, or smartphone app. Imagine if the marketing hype surrounding the recent release of Star Wars Episode VII included software that allowed you to design and then print your own custom blaster or light saber. Design and print your own Harry Potter wand.

Conclusion

The 3-D printing technology is already here. There are cheap consumer level printers, more robust prosumer printers, and high-end professional printers, mirroring many technologies currently in widespread use.

Applications are lagging a bit behind the technology itself, but they will come. It is possible that in the near future some company will combine a consumer-level decent quality 3-D printer with a killer application, and then we will see an explosion of adoption. Three-D printers will become like drones were this year, or like smart phones were after the iPhone came out. They will be the holiday gift everyone wants.