Dec 21 2021

Fiber Batteries

Technophiles talk a lot about batteries because they are so essential to our electrified and green future. By historical standards we have cheap and powerful batteries today, but because they are so critical to our technological infrastructure, any way they can be incrementally advanced is welcome, and some advances may be game-changers. While there is a lot of focus on energy density (energy storage per volume) and specific energy (energy storage per mass), many other features are important to overall battery utility. One we do not often speak about is the shape of the battery, or the ability to take on a variety of shapes. I have a feeling we might be talking about this feature more in the future.

Technophiles talk a lot about batteries because they are so essential to our electrified and green future. By historical standards we have cheap and powerful batteries today, but because they are so critical to our technological infrastructure, any way they can be incrementally advanced is welcome, and some advances may be game-changers. While there is a lot of focus on energy density (energy storage per volume) and specific energy (energy storage per mass), many other features are important to overall battery utility. One we do not often speak about is the shape of the battery, or the ability to take on a variety of shapes. I have a feeling we might be talking about this feature more in the future.

Imagine, if you will, a car that does not contain a large battery, it is a large battery. The structural components themselves double as battery storage. The same can be true for any part of your house, the casing of a laptop computer, or the structure of any electronic device, like a cell phone. Further, if batteries could be made into very thin fibers, then they could be woven into any shape. They could be thin, flexible, and woven into fabrics.

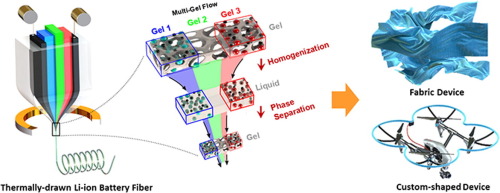

That is exactly what a team from MIT has accomplished. They created a process by which a lithium-ion battery can be stretched into a thin fiber, while maintaining the structural arrangement and integrity of all of its components. The battery fiber can then be coated in a protective material, making it waterproof. The authors write:

Here, we present a Li-ion battery fiber, fabricated for the first time using a thermal drawing method which occurs with simultaneous flows of multiple complex electroactive gels, particles, and polymers within protective flexible cladding. This top-down approach allows for the production of fully-functional and arbitrarily long lithium-ion fiber batteries. The continuous 140 m fiber battery demonstrates a discharge capacity of ∼123 mAh and discharge energy of ∼217 mWh.

They made the battery fiber 140 meters long to demonstrate that they could make it of any length. It could be spooled like thread, and then woven into a garment using standard techniques and machinery. You could have a jacket, for example, that is a battery. You could use it to power devices incorporated into the jacket, or to recharge your phone. With such fibers you could 3D print into any continuous shape desired. Imagine if every solar panel had its own battery built into its structure. Perhaps the fiber meshes could be hardened, like fiberglass, into rigid shapes.

This is the kind of technology that changes the rules for designing other technology and applications. Right now we have only a gen 1 version of the battery fiber, and the listed energy capacity is quite low. This is still suitable for small electronic devices, but we would need to see some calculations to determine if it is practical for larger applications, like cars or even laptops. Even in its current form it could be very useful, but as the technology improves, the range of applications will also grow. This is also where the imagination of the marketplace takes over. The potential seems great, and eventually someone will likely come up with a “killer-app” that everyone will want to have.

It’s like LED lights. The ability to have bright, colored, super-low energy lights not only creates a way to do things we are already doing but more efficiently, it creates the potential to do new things the old technology could not even do. There are lots of little applications I never thought of, but I’m glad someone did – like have a small ring of light on my power cord to confirm that the cord is indeed plugged in and receiving power. The ability to have almost anything double as a battery is similar. I wonder what ideas will in retrospect seem so obvious (like wheels on luggage) that you’re embarrassed to not have thought of it yourself.

Also, applications will not be limited to those in which the fiber battery can supply all of the needed power. If we go back to electric cars, for example, perhaps the range will not be sufficient using only fiber batteries built into the car’s structure. So what? Maybe this will give have the desired range, and the other half has to come from a dedicated battery. The question is – will the resulting system be cheaper and/or lighter than one without a structural battery? Engineers can play with a lot of variables. An all-electric plane may become more feasible if a large chunk of the required battery storage is in the fuselage of the plane itself.

We also have to think of many different industries and applications. Medical devices come to mind – small, flexible, waterproof devices that only need a small amount of power could be a perfect fit for this technology. There are lots of specialized jobs and applications that only someone who is familiar them will think about how a flexible fiber battery could be used.

The flexible thin fiber battery is something that researchers have been working on for a while. It’s like the light-bulb – there were many iterations contributed to by many inventors, but at some point it crossed over that fuzzy line (partly by Edison, but also by Swan) into a commercial product. So again, the real question is, has this advance brought fiber battery technology over the line into a commercial product? That remains to be seen, and is really only observable in retrospect. We will see if production can be scaled up in a cost-effective way, and if ultimately the technology market deems it worthy. Perhaps more incremental advances are necessary to truly cross the line. This advance does sound very promising, however, and it would not surprise me if we are on the cusp of a significant technology change brought about by some version of this tech.