Sep 13 2021

Using Solar Power to Make Ammonia

Ammonia is the second most produce industrial chemical in the world. It is used for a variety of things, but mostly fertilizer:

Ammonia is the second most produce industrial chemical in the world. It is used for a variety of things, but mostly fertilizer:

About 80% of the ammonia produced by industry is used in agriculture as fertilizer. Ammonia is also used as a refrigerant gas, for purification of water supplies, and in the manufacture of plastics, explosives, textiles, pesticides, dyes and other chemicals.

In 2010 the world produced 157.3 million metric tons of ammonia. The process requires temperatures of 400-600 degrees Celsius, and pressure of 100-200 atmospheres. This uses a lot of energy – about 1% of world energy production. The nitrogen is sourced from N2 in the atmosphere, and the high pressure and temperatures are necessary to break apart the N2 so that the nitrogen can combine with hydrogen to form NH3 (ammonia). The hydrogen is sourced from natural gas, using up about 5% of the world’s natural gas production. About half of all food production requires fertilizer made using this process (the Haber-Bosch process). This is not a process we can phase out easily or quickly.

It does represent, however, a huge opportunity for increased efficiency, saving energy and natural gas, and reducing the massive carbon footprint of the entire process. We know it’s possible because bacteria do it. Some plants have a symbiotic relationship with certain soil bacteria. The plants provide nutrients and energy to the bacteria, and in turn the bacteria fix nitrogen from the atmosphere (at normal pressures and temperatures) and provide it to the plant. These plants (which include, for example, legumes) therefore do not require nitrogen fertilizer. In fact, they can be used to fix nitrogen and put it back into the soil.

As a side note, this is why there are research programs trying to reverse engineer this process, so that more crops can be genetically engineered to obtain their nitrogen in the same way. If successful this would dramatically improve the efficiency of agriculture, reducing inputs and reducing negative effects on the environment (from nitrogen runoff, for example).

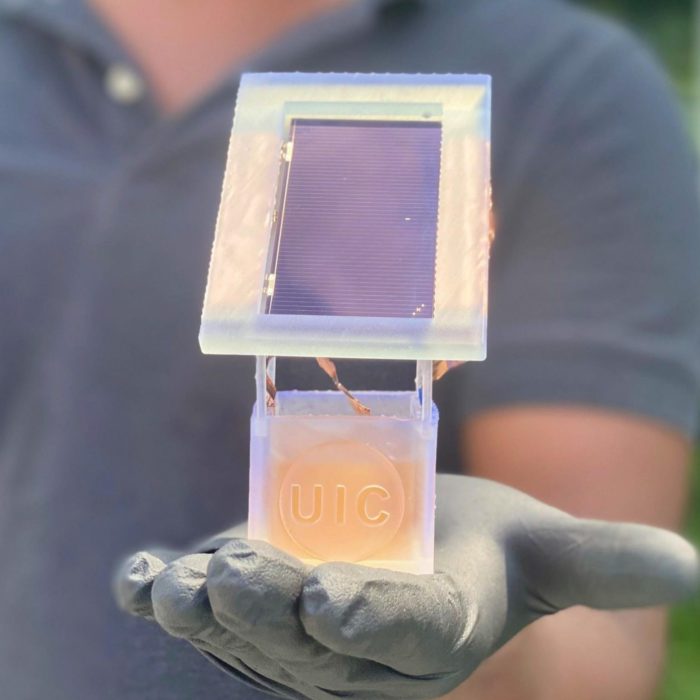

In the meantime, producing ammonia on an industrial scale without having to use lots of energy or natural gas would also be a huge boon. There are several endeavors to do just that, but none so far have scaled up to industrial levels in a cost effective way. A recent study shows proof of concept for one promising method. They use solar power to drive electrochemical synthesis of ammonia (rather than using heat and pressure). Other researchers have successfully done this, but with very low “solar to fuel” efficiencies (<1%) which are not industrially useful. The current approach has two potentially big advantages. The first is that they source the nitrogen from nitrates in waste water. If successful, the process could therefore kill two birds with one stone, removing harmful nitrates from waste water, and producing ammonia.

The second big advantage of this process is that it is 11% efficient, more than ten times the efficiency of prior methods. The authors believe this will allow the process to be scaled up to industrial levels (always the tricky part with these proof-of-concept laboratory demonstrations). One downside is that the process still requires free hydrogen as an input. As I discussed recently, free hydrogen itself is a very useful compound but does not exist in significant amounts on Earth and has to be made by liberating hydrogen from a hydrogen-containing compound (can be water, natural gas, or other chemical). Perhaps this process can be combined with electrolyzing water to make hydrogen, also using solar cells. In any case, we still need a process to mass produce lots of “green” hydrogen.

Other researchers are taking different approaches to the problem. A Japanese lab, for example, is trying to reproduce the activity of nitrogenase, the enzyme in soil bacteria that allow it to fix nitrogen from the air. They use a molybdenum-based catalyst to fix nitrogen from air, and they source the hydrogen from water (like the bacteria), rather than needing free hydrogen. Their process, however, is designed more to be a “desktop” process, making it accessible to those without the resources to build massive factories. It likely will not scale up to replace existing ammonia production, however.

It’s still too early to tell which specific method will eventually replace the Haber-Bosch process as the primary source of ammonia and therefore nitrogen fertilizer. This is worthwhile research, with significant potential gains if an industrial-scale process can be found. Ideally a process that sources nitrogen from air or waste, and hydrogen from water (rather than free hydrogen or fossil fuel) will be found. The potential energy savings are enormous. It would also help if any big staple crops could be engineered to fix their own nitrogen. If half of crops could do that, the other half could get their nitrogen from manure, and we could virtually eliminate the need for artificial nitrogen fertilizer. There would still be an industrial need for ammonia, just greatly reduced. It would be great if that ammonia were not dependent on fossil fuels or an energy-intense process.