Jul 29 2021

Engineered Synthetic Fiber – Stronger than Steel

One of the goals of material science is to create a super-strong fiber which can be easily mass produced at arbitrary length. Such fibers would be incredibly useful – for rugged clothing and gear, armor, strong cables, and manufacturing. The ultimate threshold is a cable with enough tensile strength to make a space elevator on Earth feasible. Right now we do not have a material that can do this (whether or not we would want to is a separate question).

One of the goals of material science is to create a super-strong fiber which can be easily mass produced at arbitrary length. Such fibers would be incredibly useful – for rugged clothing and gear, armor, strong cables, and manufacturing. The ultimate threshold is a cable with enough tensile strength to make a space elevator on Earth feasible. Right now we do not have a material that can do this (whether or not we would want to is a separate question).

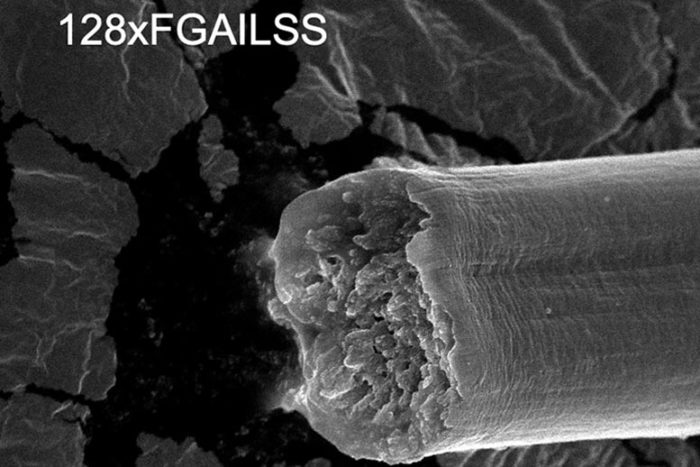

For decades some researchers have been chasing synthetic spider silk. Some spider silks have incredible strength and toughness, but it has been challenging to duplicate the proteins with the proper structure. Now a team has produced what is perhaps a viable product – a Microbially Synthesized Polymeric Amyloid Fiber. The fibers are produced by a genetically engineered bacterium. Spider silk proteins form a large number of β-nanocrystal structures, which are largely responsible for their strength. Prior attempts at creating synthetic spider silk resulted in lower numbers of β-nanocrystals, and therefore inferior properties.

The new strategy in this current study was to create a hybrid protein, adding in amyloid protein sequences. Amyloid is a protein that likes to form similar structures, and the combination proved to be useful. The resulting protein formed large numbers of β-nanocrystals, creating a fiber that is stronger than some spider silks. How strong?

There are two main properties of interest. The first is tensile strength, which is the ability to resist being pulled apart, and described usually as the “ultimate tensile strength” which is the force necessary to essentially snap a fiber by being pulled apart. Because steel is so ubiquitous and is iconic for its strength, materials are often compared to steel. Of course, there are thousands of alloys of steel, but generally those used in cables have an ultimate tensile strength somewhere between 400-550 megapascals (MPa). The new synthetic fiber has a tensile strength of “0.98 ± 0.08 GPa” – or about 1,000 MPa, about twice the tensile strength of steel.

Sometimes materials are compared to steel in terms of their specific tensile strength, which is the tensile strength divided by the density of the material. Since steel is relatively heavy, lighter materials may have a higher specific tensile strength without really being stronger than steel (but it makes for good headlines). I have been caught by this before, and so you have to be careful when reading about such materials. In this case, the study is reporting the ultimate tensile strength, no the specific strength. This material is stronger than steel.

When it comes to synthetic fiber strength, actually, Kevlar is perhaps a more meaningful comparison. That is what it is really in competition with in terms of applications, not so much steel. Kevlar has a tensile strength of 1,100 MPa, higher than the new synthetic fiber. I have also seen higher numbers for Kevlar, which may depend on the exact type and testing methods. “Spun” Kevlar has a tensile strength of 3,629 MPa. But let’s turn now to toughness. The new study claims the hybrid synthetic fiber is tougher than Kevlar. Toughness is not the resistance to stretching but the resistance to fracturing, or the force necessary to break the fibers. The toughness of the new material is give as 161 ± 26 MJ/m3, whereas for Kevlar it is about 50. The range for different species of spider silk is from 150 to 271, which is why the study says their hybrid synthetic fiber is tougher than “some” spider silks. It’s in the middle of the range.

This new material, therefore, is fairly impressive. It has a tensile strength a bit lower than the low end for Kevlar, but is tougher than Kevlar, and in the middle of the range for spider silk. Hopefully, this is just the beginning of this approach, and there is room for improvement with tweaking of the protein structure. Perhaps the real breakthrough here is getting bacteria to make the fibers with the desired protein structure, something which has proven very difficult so far.

Whether or not this will prove to be a truly useful material will likely depend on whether or not it can be economically and practically mass produced and spun into useful fibers. Something like this synthetic fiber might become the next Kevlar.

One question I had, though, that I could not find the answer to – is the usefulness of Kevlar for bulletproof vests due to its tensile strength, toughness, or both? Partly the effectiveness in stopping a bullet is due to the structure of the weave itself. It is difficult to push the fibers apart, which soaks up a lot of the kinetic energy of the projectile. But what keeps the bullet from penetrating through the fibers? It seems this would be more toughness, but I could not find an authoritative answer. (Perhaps a material engineer out there can enlighten me). If it is toughness, then the new hybrid material might be better than Kevlar for bulletproof applications.