Nov 05 2019

Another Artificial Leaf

Scientists report a new process for using sunlight to convert atmospheric carbon dioxide into oxygen and fuel. Anything that does a version of this basic process has been called an “artificial leaf” because that is what photosynsthesis does, convert CO2 and water into oxygen and glucose. The balanced equation is this: 6CO2 + 6H2O ——> C6H12O6 + 6O2, and the process is driven by energy from sunlight.

Plants evolved to do this efficiently. So, if we want an efficient system to remove CO2 from the air and make useful molecules, we can use life that already does this: plants, algae, or photoplankton. This is the basic concept of biofuels. Of course, when you burn biofuels you release the CO2 back into the atmosphere, so this isn’t a way to remove CO2 permanently, but it is a potentially carbon neutral process, with the energy ultimately coming from the sun.

I say potentially carbon neutral, because it depends how you are growing the biomass. If you are using fossil fuel based fertilizer and the farming itself is energy intensive, then you may release more CO2 than you take out. This is a limiting factor for using biofuels as a strategy for decarbonizing the energy infrastructure. Also, farming is very land intensive, and we need that land to grow food. For these reasons I don’t see biofuels as a major solution to the carbon problem. At best it can be used to recycle biomass that would otherwise be wasted to replace fuels for applications (like jet fuel) that are not easily replaced with electric motors.

The “artificial leaf” approach is very similar to the biofuel approach, except we use technology instead of biology. The key is in developing catalysts that will efficiently produce the reactions we need, getting their primary energy from sunlight. The advantage over biofuels is that if we could develop a scalable, efficient, and cost effective process it may not depend at all on farmland or large amounts of water. In the end this is an energy storage solution for solar energy, and in that manner is similar to using photovoltaics and batteries. In the case of the artificial leaf, the leaf is the photovoltaic, and the end product is the “battery” or energy storage medium.

The new process being reported uses:

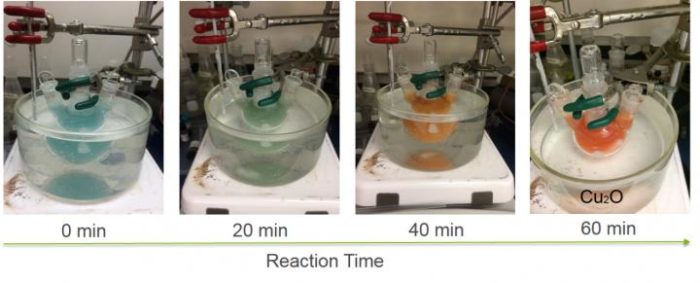

The key to the process is a cheap, optimized red powder called cuprous oxide.

Engineered to have as many eight-sided particles as possible, the powder is created by a chemical reaction when four substances – glucose, copper acetate, sodium hydroxide and sodium dodecyl sulfate – are added to water that has been heated to a particular temperature.

The process produces oxygen and methanol as end-products. Methanol is basically fuel (a high energy compound that can be burned), whether used directly or processed further into other types of fuel. That all sounds great, but the devil is always in the details, specifically – can this process be industrialized in a pragmatic and cost effective way? Does it use readily available materials, and will the resulting fuel be cost effective for the market? How big and how many factories will be needed to make a dent in our energy infrastructure? What will we do with the end product? Can it go into existing vehicles? How hard will it be to adapt the fleet to the new fuel?

High energy molecules can also be used for more than just fuel in cars. They can be feedstocks to industrial reactions, which is another significant source of CO2. Ideally we would like to replace as many processes as possible with ones that are ultimately powered by the sun, scalable, cost effective, carbon neutral, and sustainable.

Another approach is to use an “artificial leaf” reaction in order to split hydrogen and oxygen in water with sunlight. In this reaction hydrogen is the energy storage medium, and it is burned back with oxygen to produce water. The cycle is carbon neutral and relatively energy efficient. Hydrogen is also a reasonably practical energy storage medium, but it would require building a hydrogen economy infrastructure. Or – hydrogen can be used as a feedstock to produce more conventional fuel.

How viable is a hydrogen economy? I remember 20 years ago when that was all the rage, and conventional wisdom was that by today we would already be deeply into such an economy. Everyone was supposed to be driving hydrogen fuel cell cars, and there was even speculation about every home having a hydrogen fuel cell for energy, with a vast storage and distribution system of hydrogen gas. California even passed a hydrogen infrastructure bill on the theory of, “Build it and they will come.”

The California Hydrogen Highway Network (CaH2Net) was initiated in April of 2004 by Executive Order (EO) S-07-04 under Governor Arnold Schwarzenegger. The mission was to assure that hydrogen fueling stations were in place to meet the demand of fuel cell and other hydrogen vehicle technologies being placed on California’s roads.

Today California has 40 hydrogen refueling stations. So what happened to hydrogen? Unfortunately the best laid plans ran face first into reality. It turned out that the technology to store large amounts of hydrogen in a safe way usable for the energy needs of cars was a non-trivial problem. Researchers got stuck trying to pack enough hydrogen into a solid form that was stable yet able to release enough to drive the car, while also not being to big or too heavy. Cars are demanding because you have to be able to drive anything under the hood around, and crashes can’t result in giant explosions (so no highly pressurized tanks of gaseous hydrogen).

This technological hurdle resulted in a delay in the development of practical hydrogen fuel cell cars (they existed, but not with the parameters necessary to penetrate the market). This gave time for the development of hybrid and then all-electric vehicles. They have the advantage of having lower infrastructure needs, because you can charge them at home for most of your everyday use. Fast charging stations are also not difficult to deploy. Battery technology has also significantly improved in the last 20 years.

But now hydrogen fuel cell technology is not giving up, and is trying to make a comeback. Especially in Asia, auto companies are starting to but their nickle down on hydrogen. We seem to be setting the table for an epidemic technological battle between hydrogen fuel cells and electric-battery driven cars. I find this all somewhat exciting, especially since history has shown it is difficult to predict who will win this fight. I suspect both technologies will have a future, but one will emerge as the 80-90% winner with market domination.

If I had to bet I would bet on electric vehicle technology, simply because it requires less new infrastructure. In fact, a 2016 study did a direct comparison and found that electric vehicles were better for the environment than hydrogen fuel cell because of the infrastructure needs. But I think there will remain a niche for hydrogen.

It is also possible that electric vehicles will dominate in some markets, like the US and Europe, while hydrogen dominates in others, like Asia. We may, in fact, be heading for this future.

I think this is all great – let the two technologies compete. A lot will depend on which technology benefits from significant advances first. If someone develops a truly next-generation battery, then I think the fight is over. The winning strategy for hydrogen is a bit harder, it seems to me. We need both a better way to store usable hydrogen and we need an efficient way to produce large amounts of hydrogen. And these advances need to balance the increased infrastructure demands of hydrogen. But if we cannot develop a successor to lithium ion technology, and we get into a crunch with lithium sources, then hydrogen may find its opening – if the tech is ready to exploit it.

It’s actually an exciting slow-motion techno-drama, more epic than betamax vs VHS. Biofuels are a dark horse in this competition, and I have mostly written them off, again except for a niche application.

We’ll see where things are in another 10-20 years.